Lesson:

Splicing Optical Fiber With A Mechanical Splice

Objectives:

From this lesson you should learn:

How to use these tools to strip cable to the bare fiber

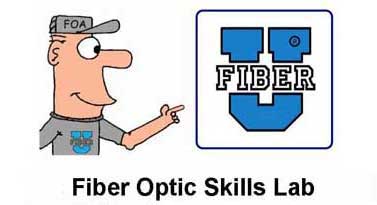

Tools:

Safety Glasses

Fiber Stripper

Kevlar Shears

Fiber Cleaver

Components:

Fiber optic cable

Splices (several for practice)

Safety:

|

Always

wear safety glasses when doing any of

these exercises and dispose of all fiber

scraps properly.

Safety

Rules - Read before beginning any

exercises.

|

Exercise

Before attempting this exercise, you should complete

the exercises on stripping

and cleaving

fibers.

1: Examine the mechanical splice. The splice has a

sleeve inside that aligns the fibers to create a splice.

The installation process involves preparing a fiber,

inserting the fiber in the splice, crimping that end,

then preparing a second fiber, inserting it until it

butts up against the first fiber to create a splice,

then crimping the second fiber. Finish

the splice by pushing the crimp section down fully.

A VFL can be used to verify the splicing process as you

can see below. Insert the connector of your cut

patchcord in the VFL and turn the VFL on. The light from

the end of the fiber will help you see the small hole on

the end of the splice where you must insert the fiber

and it will help you verify the splice has been made

properly.

We'll use this mechanical splice to splice two pieces

of your cable back together in this exercise.

2. Use the fiber stripper to cut off 4" (100mm) of the

cable jacket and pull off the cut piece.

3. Use the kevlar scissors to cut the aramid fibers at the

end of the jacket, exposing the 900micron tight buffered

fiber.

4. Use the fiber strippers to strip ~1.5" (40mm) from the

end of the fiber in 4-6 steps, about 1/4-3/8" (6-8mm) at a

time.

5.

Clean the fiber with a lint-free wipe and alcohol.

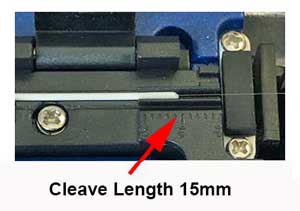

6. Cleave the fiber to a length of 15mm from the end

of the 900 micron buffer using the cleaver's stripping

gage.

Clean

up all your fiber scraps immediately after cleaving

the fiber and dispose of them in a container like a

used take-out coffee cup marked "Fiber Scraps"!

7. Insert the fiber into one end of the splice until it

stops, then push down the plastic crimp on the end to hold

that fiber. Be sure to only push the crimp at the very

end so you do not crimp both ends - that will make it

impossible to insert the second fiber.

8. Repeat with the second fiber - strip/clean/cleave -

then insert the fiber in the other end of the splice.

Watch the VFL light to see how the light increases out of

the fiber as the splice joint is made. When you get the

brightest light, crimp the second fiber, then push the

crimp down fully.

Watch this to

see how it's done:

9.

Practice this exercise several times with the splices

supplied. Be sure to keep several splices if you need to

do demonstrations to your instructor.

You have successfully completed this exercise

when you have made several splices that show low

splice loss and good light through the splice.

After

successfully splicing fiber several times, fill in your

Scorecard.

Learn the "splicers mantra" - "strip - clean -

cleave - splice"

Return

to Lesson Plan

This information is

provided by The Fiber Optic Association, Inc. as a

benefit to those interested in teaching, designing,

manufacturing, selling, installing or using fiber optic

communications systems or networks. It is intended to be

used as an overview and/or basic guidelines and in no

way should be considered to be complete or

comprehensive. These guidelines are strictly the opinion

of the FOA and the reader is expected to use them as a

basis for learning, as a reference and for creating

their own documentation, project specifications, etc.

Those working with fiber optics in the classroom,

laboratory or field should follow all safety rules

carefully. The FOA assumes no liability for the use of

any of this material.

|